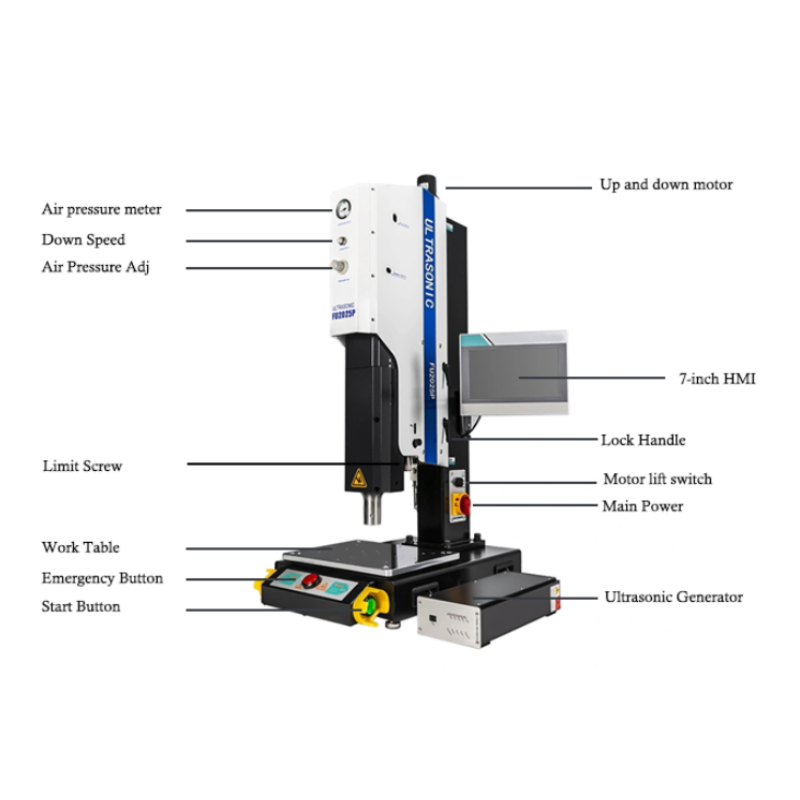

CDsonic CD-X2000 Series Ultrasonic Welding Machine – Technical Overview

Precision & Stability

100% Digital Ultrasonic Generator

-

Real-time auto-frequency tracking (±0.1% accuracy)

-

Adaptive circuit protection (overload/overheat/short-circuit prevention)

-

Three welding modes: Time | Energy | Time + Energy

Smart Amplitude Control

-

Fixed / Time-stage / Energy-stage amplitude adjustment

-

Ensures optimal energy delivery for different materials

High-Precision Controls

-

Auto-balancing & limit systems for consistent weld depth

-

Programmable lifting system for smooth operation

User-Friendly Operation

7-Inch Touchscreen HMI

-

Intuitive parameter setup (100+ recipe storage)

-

Real-time monitoring (energy, pressure, time graphs)

-

Data logging & export (CSV/USB) for quality traceability

Versatile Integration & Customization

🛠️ Expandable Options

-

X/Y-axis moving tables (for automated positioning)

-

Soundproof enclosures (noise reduction to <75dB)

-

Film roll feeders (for sequential welding)

Industrial-Grade Design

-

Heavy-duty steel frame

-

Pneumatic pressure system (0.2–0.8MPa adjustable)

-

Optional cooling modules for high-duty cycles

Reliable Performance for Demanding Applications

Rigorous Pre-Shipment Testing

-

48-hour continuous weld validation

-

Material compatibility tests (ABS, PC, PP, nylon, etc.)

Why Choose CD-X2000?

Stable & Repeatable Welds – Digital control eliminates manual errors

Easy to Use – Touchscreen interface reduces training time

Future-Proof – Modular design supports automation upgrades

Cost-Effective – Low energy consumption vs. hot plate/vibration welding

Price Range: Competitive with industry standards (contact for customized quotes)

Delivery: 3–7 days (standard models) | 2–4 weeks (fully customized)

Ideal for: Automotive, medical, electronics, packaging, and consumer goods welding.